Pure Dry Goods Technology Sharing Post: 6 Morphological Changes of White Sugar in The Process of Frying Sugar, Sugar Water, Frosting, Silk Drawing, Glass, Tender Juice, Sugar Color

1.

Simply put, put the white sugar or crushed rock sugar in the pot, and according to the needs of the dishes you are going to make, choose to add an appropriate amount of water or oil for frying, and control the appropriate temperature to fry the white sugar to your own Process that requires status.

There are two basic methods of frying sugar: water frying or oil frying. It's best to boil sugar juice and make frosting with water; to make silk, glass, tender juice and sugar color, you can either stir in water or oil.

2.

When white sugar or rock sugar is added with a proper amount of water or oil, under the condition of continuous heating, it will experience six state changes successively, namely, sugar water, frosting (also called icing sugar), wire drawing, glass, tender juice and sugar color.

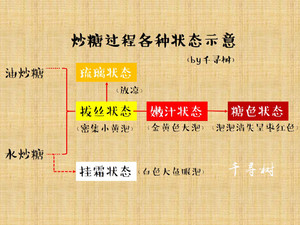

3.

Combined with this picture, everyone can understand more clearly the various state changes and the sequence in the process of frying sugar.

4.

Sugar water, or syrup, is the first state achieved in the process of frying sugar. Put sugar and appropriate amount of water in the pot, heat it on a low fire until the sugar is completely melted, and the water is gradually evaporated to form a sugar solution.

Precautions:

(1) Decide the concentration of the sugar juice according to the needs of the dishes. For dishes with high water content, the sugar juice can be slightly thickened, such as apples in sugar water, kumquats in sugar water, etc.;

(2) If the water content of the raw material is low, the sugar juice can be boiled a little thinner, such as sugar water yam, beeswax lotus seeds and so on.

(3) It is best to stir-fry the syrup with water.

5.

Hanging frosting, or icing frosting, is the second state achieved in the process of frying sugar.

The principle of frosting is the recrystallization of sugar: After the sugar liquid has experienced the state of sugar water, it continues to be heated. With the continuous evaporation of water, the concentration of the sugar liquid gradually increases. When the concentration of the sugar liquid reaches the critical point, the sugar liquid becomes When the supersaturated solution is over, put the raw materials into the pot and spread the sugar liquid, turn off the heat, and continue to stir. As the temperature decreases, the white sugar will precipitate again in the form of crystals. This phenomenon is also called turning sand. Or return to sand.

6.

The liquid sugar in the frosting stage is suitable for dishes such as frosted balls, frosted peanuts (that is, peanut sticks), and hawthorn sugar snowballs.

Precautions:

(1) When boiling the sugar liquid, the firepower should be small and concentrated at the bottom of the pot to avoid the sugar liquid on the side of the pot from being coked and turning yellow due to excessive heat;

(2) After the raw materials are put into the pot and coated with sugar liquid, turn off the heat and stir continuously, and spread before the raw materials crystallize to avoid sticking together;

(3) Before frosting the raw materials after frying, the oil must be controlled dry, otherwise it will affect the effect of frosting;

(4) To make the frosting, it is best to use the method of frying sugar in water to avoid the sugar liquid from being badly coated on the raw materials due to oil.

7.

Silk drawing is the third state reached in the process of frying sugar. After the sugar water and frosting state, the sugar liquid continues to be heated. After the temperature exceeds the melting point of the white sugar, the white sugar will melt again and become a liquid. The sugar liquid begins to caramelize, causing the sugar The color of the liquid slowly turns yellow. When the color of the sugar liquid turns to light yellow (equivalent to the color of sesame oil), put the fried semi-finished product into the pot, coat it well, put it in the pot, and pull it out while it’s hot. A uniform and slender sugar thread.

8.

The sugar liquid in the state of drawing is very suitable for making all kinds of toasted dishes, such as toasted apples, toasted bananas, toasted sweet potatoes, toasted yam and so on.

There are three common methods of drawing silk and boiled sugar: water drawing, oil drawing, and mixed drawing with water and oil.

9.

Put sugar in the pot and add clear water. As long as the amount of water can melt and boil the sugar, open the fire and boil, go through two stages of sugar water and frosting. Continue heating, the white sugar crystallizes, and reheat, the precipitated white sugar melts into a liquid again. When the color becomes a light yellow sesame oil color and there are small bubbles on the surface, it is the best time to draw the wire. Quickly add the fried ingredients, coat them with the sugar liquid, and put them in the pan.

10.

Put a small amount of oil in the pot, not too much oil, as long as it can moisturize the pot, add white sugar and continue heating on low heat until the sugar liquid turns into a light yellow sesame oil color, add the ingredients, coat well, start the pot and put on the plate. Up.

11.

Put white sugar in the pot, add a little water and boil it until the sugar melts. When the sugar liquid reaches the frosting state, pour a little oil and boil until the sugar liquid is light yellow sesame oil color, and then add the raw materials and coat the sugar liquid. Put the pot on the plate.

Precautions

(1) The process of boiling sugar and wire drawing requires a low fire. After entering the wire drawing stage, the various states of the sugar liquid change very quickly, so the sugar must be boiled on a low fire.

(2) The raw materials used for wire drawing must be kept at a certain temperature after frying, otherwise it is not easy to coat the sugar liquid.

(3) The oil pulling time is short, and the vegetables become faster; the water pulling speed is slow, but it is easier to control.

(4) The best time to draw silk is when the sugar liquid is boiled to light yellow sesame oil color.

12.

The glazed state is actually a manifestation of the wire drawing state, which is very different from the wire drawing state. The glazed state appears about 3-5 seconds after the wire drawing state. The color of the sugar liquid appears amber. When the sugar liquid in the glazed state After cooling, a layer of amber-colored hard shell can be coated on the raw material, and the taste is crisp and does not stick to the teeth.

Nowadays, most of the two states of wire drawing and colored glaze are classified into one type. The raw materials are put into the sugar liquid in the state of wire drawing and coated. If it is eaten hot, it is a wire drawing dish. If it is cooled, wait for the raw material to be coated with a layer of amber. After eating the sugar shell, it is the colored glaze dish. The hawthorn of the candied haws is wrapped with a layer of liquid sugar in the state of glaze. There are hollow glaze balls and meat in the state of glaze.

13.

Tender juice and sugar color are obtained by frying the sugar until it is liquid, then add hot water and boil it evenly. The difference between tender juice and sugar color is the degree of frying the sugar liquid and the timing of adding boiling water.

14.

To clarify the tender juice and sugar color, we must start with the fried sugar color:

First of all, frying sugar color is only a process, not a specific product. The process of frying sugar color obtains two products, tender juice and sugar color.

The color of fried sugar is to put white sugar or crushed rock sugar into a pot and heat it. The sugar melts and turns into sugar liquid. As the heating continues, the sugar liquid will undergo a caramelization reaction. When part or all of it is coked, add boiling water and boil it. 5- In 10 minutes, you got the sugar color.

According to the different degree of frying, that is, the different degree of caramelization reaction, the frying sugar color process can get two kinds of products: tender juice and sugar color.

15.

After the white sugar is fried into tender juice or sugar color, the sweetness will be reduced, the color is bright red or maroon, and it has a strong aroma, which can color and enhance the flavor of dishes. It is a natural flavoring and coloring technique.

Although there are many ready-made finished sauces that can be used for color mixing, such as various braised soy sauces. Although it is convenient and quick to use, the tender juice and sugar color impart the unique aroma and color to the dishes. Other condiments cannot be used. Replacement.

16.

The comparison of braised soy sauce, icing sugar and tender sauce is shown in the figure.

17.

Cooked dishes and grilled dishes that are red or sauce-red in color generally need to be fried in sugar, such as braised pork, braised fish, dried fish, braised knuckle, roasted duck, roasted tendons, etc.;

In addition to dishes, sugar is also used when preparing miso soup for sauced meat or braised meat. Now many chefs have simplified the process of frying sugar coloring. It is convenient to use soy sauce or other condiments or even coloring agents to help color them.

18.

In the process of frying sugar color, about half of the white sugar is converted into caramel, and when the aroma is released (the sign of the sugar liquid at this time is the appearance of golden yellow bubbles), the sugar liquid obtained after adding boiling water and boiling is called tender juice or Tender sugar color.

19.

The fried tender sauce has a very bright red color.

20.

Since there is uncoked white sugar in the tender juice, the tender juice still has a certain sweetness and light color. It is suitable for making dishes with bright red color and sweet taste, even after a long time of cooking and harvesting. Juice, the color of the finished dishes will not be too dark.

21.

During the frying sugar color process, almost all the white sugar is converted into caramel, and when it emits a strong caramel smell (the sign of the sugar liquid at this time is showing chicken blood red or maroon red), add the sugar liquid obtained after boiling in boiling water It is called sugar color.

22.

Since the white sugar in the sugar color is basically caramelized (please note that it is caramelized, not charred. If the fried sugar color is black and bitter, it means that it has been fried and cannot be used for cooking), so the sugar color is basically There is no sweetness, the caramel content is higher, the caramel smell is more intense, and the color is deeper.

23.

It is suitable for making darker-colored dishes, such as grilled knuckles, grilled pomfret, etc.

24.

There are three methods for frying in sugar color, frying in water, frying in oil, and frying in water and oil.

25.

Put sugar in the pot, add appropriate amount of water (you can melt the sugar), slowly heat it on a low fire, the water is evaporating at the beginning, and then go through the wire drawing state, the tender juice state, and then reach the sugar color state, the sugar liquid When the chicken blood is red, add boiling water and boil for 5 minutes, and it will become water-fried sugar color.

It takes a long time to stir-fry the sugar color with water. The advantage is that the changes in various states are relatively slow, it is not easy to over-fry, and it is easier to master.

26.

Put oil in the pot to moisten the pot, pour out the excess oil (a little bit of oil left when moistening the pot is fine), put in sugar, heat it on a low fire, the sugar liquid will melt quickly, and then go through the state of wire drawing and tender juice. After the state reaches the sugar-colored state, add boiling water and boil for 5 minutes to become the oil-fried sugar-colored state.

Frying sugar with oil is quicker, but it is difficult and requires sufficient experience.

27.

Put sugar in the pot, add a small amount of water, boil until the sugar melts, pour a little oil and continue to cook on a low fire, go through the wire drawing state and the tender juice state to the sugar color state in turn, add boiling water to boil and the sugar color is ready. The time for frying sugar with water and oil is between water frying and oil frying, and the color of the boiled sugar is more translucent and red.

Precautions

(1) You don't need to put too much oil in the fried sugar color. Too much oil will cover the sugar liquid, which will not only affect the operator to observe the color of the sugar liquid and adjust the temperature, but also increase the oiliness of the dishes.

(2) Extremely important! ! ! ➡️After the sugar liquid is fried to tender juice or sugar-colored state, be sure to add boiling water. If you add cold water, the temperature of the sugar liquid will be too high and the temperature of the water will be low, resulting in excessive temperature difference, and the sugar liquid will splash around and burn your skin. . This is because water starts to boil at 100 degrees under normal pressure, and oil may need to be 200-300 degrees. The temperature of the syrup when it is fried to the sugar-colored state is also much higher than 100 degrees, so when the water is poured into the sugar liquid, The water immediately boils, producing a large amount of steam that expands rapidly, causing the oil and syrup to splash everywhere. The solution is: when you pour water, you must pour hot water, preferably just boiling water, to minimize the temperature difference between the water and the sugar liquid.

(3) After adding boiling water, the fried sugar color should be boiled for 5 minutes, so that the tender juice or sugar color will be more stable and the color will be more even.

(4) The fried tender juice or sugar color, if it is not used up at one time, you can save it for the next time. In summer, you need to store it in the refrigerator. If the tender juice or sugar color smells sour, it means that it has deteriorated and cannot be used. .

28.

Actually operate the two sugar frying methods, water frying and oil frying, and explain the changes in the sugar frying process in detail.

29.

From step 30 to step 49 is the actual operation of the whole process of frying sugar.

30.

(1) Put white sugar in a clean wok.

31.

(2) Add a small amount of water, the amount of water that can melt the white sugar is enough, the amount of water added is not particularly important, and the added water will take longer to boil.

32.

(3) Turn on a small fire and start heating, the white granulated sugar begins to dissolve in the water, and after all is dissolved, it becomes sugar water, and enters the first state of the sugar frying process-sugar water state.

33.

(4) At this time, the sugar liquid has big white bubbles, which is because the water in the sugar liquid is constantly evaporating.

34.

(5) Look carefully, the concentration of the sugar solution is changing, and the bubbles gradually begin to become uniform. At this time, the sugar solution is still in the state of sugar water, but the concentration is constantly increasing.

35.

(6) The concentration continues to increase, while the water in the sugar solution is constantly evaporating, and the bubbles are denser and more uniform.

36.

(7) At this time, the sugar liquid is almost close to the saturated solution state, and the sugar liquid is in a relatively thick sugar water state.

If you are making syrup, beeswax, or honey sauce, you can put the raw materials into the pot between steps 3 and 7 according to the required concentration of the syrup, turn it over and put it on the pot. .

37.

(8) Continue heating the saturated liquid sugar, and you can see that the white bubbles become denser and smaller. When you turn it with a spatula, you can feel a little rustle, which indicates that the sugar liquid is in a supersaturated state. , The white sugar precipitates again in the form of crystals, that is to say, it has begun to turn the sand and reached the second state of fried sugar-the frosting state.

If it is to make frosted dishes such as frosted peanuts, hawthorn sugar snowballs, frosted balls, etc., this time is the best time to add the ingredients. After the ingredients are put in the pot, turn off the heat and continue to stir fry. As the temperature decreases, the sugar The sand will be wrapped on the surface of the raw material, forming a layer of snow-white frosting.

38.

(9) Continue to heat the sugar liquid that has reached the frosting state. When you stir the sugar liquid with a spatula, you will feel the rusty feeling from the frosting state and begin to become smooth. This is because the white sugar crystallized after sanding is heated. It broke through the melting point and melted into a liquid again; at the same time, the caramelization reaction began. It can be seen that the color of the sugar liquid began to change a little bit, with a little yellow.

39.

(10) As the caramelization reaction progresses, the color of the sugar liquid obviously begins to turn yellow, indicating that more and more white sugar has undergone a coking reaction.

40.

(11) Continue to heat the sugar liquid. The firepower at this time must be the minimum fire. The state of the sugar liquid at this stage changes extremely fast. When the sugar liquid shows this light yellow, imagine the color of the sesame oil at home, and it is dense and small. The state of yellow bubble indicates that it has entered the third state of frying sugar-wire drawing state. At this time, put the fried raw materials into the pot, evenly coat the sugar liquid, lift the pot to the plate, and pull out the even and slender sugar shreds when it is hot and eaten.

41.

(12) If you continue to heat the sugar liquid, more white sugar participates in the caramel reaction, and the color of the sugar liquid is obviously golden.

42.

(13) Continue to heat on a small fire. When the sugar liquid turns amber, the fried sugar reaches the fourth state-the glazed state. The glazed state and the wire drawing state are very close, and it will reach the glazed state in a few seconds after the wire drawing state. At this time, add the raw materials and coat them evenly. After cooling, the surface of the raw materials is a layer of amber hard shell. Take a hawthorn and roll it in the glassy sugar liquid. After cooling, it will be a candied haws.

43.

(14) Continue to heat and proceed to the next state.

44.

(15) The color of the sugar liquid began to turn golden, and the bubbles began to grow larger.

45.

(16) When the sugar liquid is golden yellow and there are many big bubbles, it is the fifth state of fried sugar-tender juice state.

46.

(17) If boiling water is added to the sugar solution in the state of step 16, it can be boiled into tender juice.

47.

(18) If you choose to continue heating in step 16, you can see that the color of the sugar liquid changes from golden to yellow to red.

48.

(19) Continue heating until the sugar liquid is maroon red (chicken blood red) and the big bubbles begin to disappear. This is the sixth state of fried sugar-sugar color state.

49.

(20) At this time, add boiling water to the sugar solution and boil it out to be the color of water-fried sugar.

So far, the whole process of water-frying sugar frying has been completed, and the six states in the process of frying sugar are also presented in sequence.

50.

From step 51 to step 64 is the actual operation of the whole process of frying sugar.

51.

(1) Put sugar in a clean wok.

52.

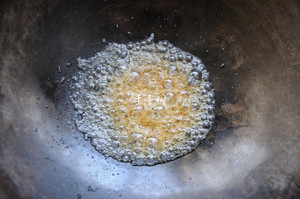

(2) Add 1 spoon of oil, the amount of oil does not need to be too much, please refer to the explanation of Note (1) in 2.6.2.

53.

(3) Turn on a small fire and start heating.

54.

(4) Since the water temperature is 100°C under normal pressure, and the oil temperature can easily exceed 100°C, the sugar will soon begin to melt instead of melting. Use a spatula to quickly smooth the sugar liquid to avoid uneven heating.

55.

(5) The white sugar will soon become the state shown in the picture, and then it will start to melt.

56.

(6) The sugar has almost completely melted.

57.

(7) When the sugar liquid shows a light yellow sesame oil color, it has reached the state of wire drawing of the sugar liquid. At this time, add the raw materials and coat them well and you can pick up the pan and serve it while it is hot and start to wire. At the same time, it can be seen from the picture that if too much oil is added, it will affect the operator to observe the color change of the sugar liquid.

58.

(8) The sugar liquid begins to bubble up from the bottom of the pot.

59.

(9) There will soon be dense small bubbles floating up from the bottom of the pot.

60.

(10) When the sugar liquid starts to show big golden bubbles, this stage is the tender juice state.

61.

(11) Add boiling water in the state of step 10 to boil the fried juice.

62.

(12) Continue heating in the state of step 10, the color of the sugar liquid begins to turn to maroon, and the big bubbles that have started to disappear.

63.

(13) Add boiling water to boil, it must be boiling water (otherwise it will fry everywhere).

64.

(14) After 5 minutes, the product is fried in oil and sugar.

At this point, the entire process of frying sugar with oil has been completed. It can be seen from the process that the speed of oil frying is faster than that of water frying, but the process of frying requires rich experience.

65.

This method of frying sugar color is between water frying and oil frying. Specifically, after the sugar is boiled, pour a little oil into the pot and continue to boil it on a low fire, and then go through the wire drawing state and the tender juice state to the sugar color state. Boil in boiling water and it will turn into sugar color. The purpose of pouring the oil in the water during the stir-frying is to use the high temperature of the oil to make the sugar break through the melting point faster and speed up the melting speed of the sugar. The other methods are no different from the other two sugar-color stir-fry methods, so I won't repeat them.

Tips:

postscript:

The original idea of writing this article was to share the experience of candied apples with everyone. As a result, the more I wrote, the more I wrote, so I simply summarized the whole process of frying candies. After writing for several days, we finally made frying candies, a must-have for a chef. The basic skills have been summed up, and I finally realized the feeling of painstaking effort.

From the ground up, whether you want to make perfect icing and candied vegetables, or to make tender juice and sugar color to make perfect braised dishes, frying sugar is an essential basic skill. I hope you will learn from it. Useful knowledge can be obtained in this article.

It is inevitable that there will be omissions in the article, and everyone is welcome to criticize and share in the comment area.